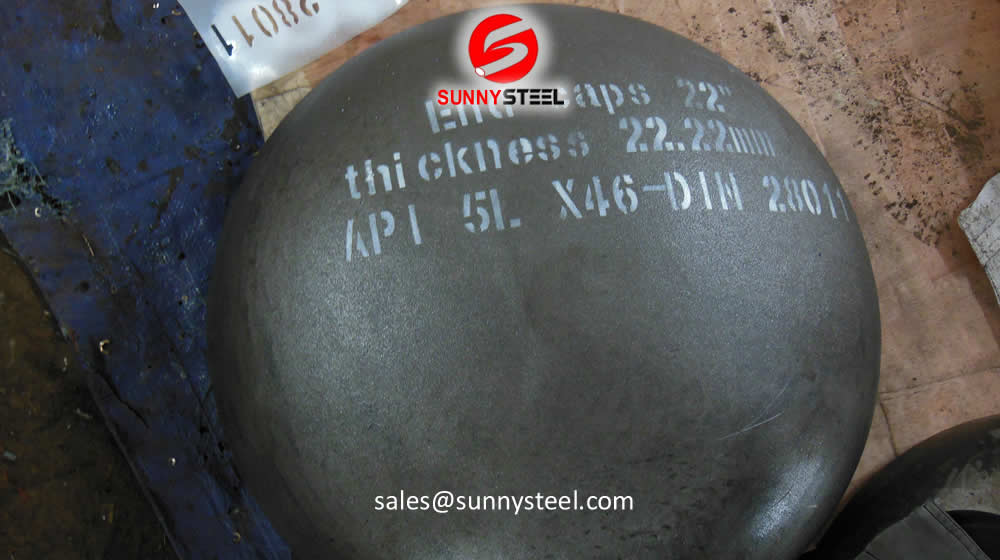

End Cap

End caps are usually used for protecting the end of pipe and other fittings, so the shape are designed according to the shape of pipe line.

End caps are widely well-known for the utmost output and outstanding results that it gives.

Size range:

- Out diameter: 1/2"-60" DN15-DN1500

- Wall Thickness: sch10-80s

- Pressure: SCH5 to SCH160v

- Max. wall thickness: 200mm

Bending, squeezing, pressing, forging, machining and more

Socket pipe cap

Socket welding pipe cap also known as high pressure pipe cap, forging steel pipe cap, nominal size: 1/4 "- 5", DN20-DN200, applicable medium: water, steam, oil etc.

The socket pipe cap quality directly affects the operation of the pressure vessel. For the forming of tailor-welded before and after the split forming butterfly head welding tests, it is very important.

Manufacturing Standards of Buttweld Pipe End, Buttweld Pipe Cap

- ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43

- DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

- EN: EN10253-1, EN10253-2

- ASTM A403 – ASME SA403 Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

- ASME B16.9 Factory-Made Wrought Fittings Buttwelding

- ASME B16.25 Buttwelding Ends

- ASME B16.28 Wrought Steel Short Radius Elbows and Buttwelding Returns

- MSS SP-43 Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

Buttweld Pipe End Material Grades

- Stainless Steel Pipe Cap ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Pipe Cap ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Pipe Cap ASTM A420 WPL3, A420 WPL6

- Alloy Steel Pipe Cap ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Pipe Cap ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462

- Nickel Alloy Pipe Cap ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Deep Drawing method of end caps

One of the most common manufacturing methods for caps, where plate is cut out in a circle and formed by deep drawing.

Deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die.

A drawing press can be used for forming sheet metal into different shapes and the finished shape depends on the final position that the blanks are pushed down in. The metal used in deep drawing must be malleable as well as resistant to stress and tension damage.

How to get high quality pipe cap?

Pipe cap acts as protective device and are designed to protect pipe ends of various shapes. The main purpose of using pipe caps is to waterproof the connections. They are also used to close the the ends of hydraulic or pneumatic pipes and tubes. They are used in the plumbing apparatus of domestic, commercial and industrial water supply lines, machinery and processing equipment etc. They are also fitted on water pump lines with the sole purpose of removing air blocks. Pipe caps are highly demanded as an important category of pipe fittings. If a solvent-weld cap is used to provide for a future connection point, several inches of pipe must be left before the cap; when the cap is cut off for the future connection, enough pipe must remain to allow a new fitting to be glued onto it.

How to connect pipeline with pipe cap?

Pipe Cap is directly welded to die at the end of the pipeline; at the end of the pipeline can also welding flange, then with a blind flange to death, when necessary can open the blind flange, pipeline check inside. The conventional cap holder with pressure pressing made by thick wall; forging; by spinning large diameter. The need for maintenance or even after the connecting line, with blind, not later, with a pipe cap. With the blind plate has the possibility of leakage, there is a long time, and screw rust died, as useless, the heat pipe is not very easy to heat insulation.

SURFACE TREATMENT:

- Transparent oil, rust-proof black oil or hot galvanized.

- Special design available All the production process are made according to ISO9001:2000 strictly.

- Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

- Depending on their construction, pipe caps contain threaded cap, tapered cap and anti-roll cap etc.

Applications of end caps:

End caps are widely used in various commercial and industrial applications. Industrial applications include:

- Chemical processing

- Petroleum

- Pulp/paper

- Refining

- Textile

- Waste treatment, Marine

- Utilities/power generation

- Industrial equipment

- Automotive

- Gas compression

- Distribution industries

- Industrial plant fluid power systems.

End caps FAQs

Pipe Cap are used for connecting pipes of different diameters and find wide applications in various chemicals, construction industries, paper, cement & ship builders.

Bevelled Ends

The ends of all buttweld fittings are bevelled, exceeding wall thickness 4 mm for austenitic stainless steel, or 5 mm for ferritic stainless steel. The shape of the bevel depending upon the actual wall thickness. This bevelled ends are needed to be able to make a "Butt weld".

Welding Bevel acc.to ASME / ANSI B16.9 and ASME / ANSI B16.28

ASME B16.25 covers the preparation of buttwelding ends of piping components to be joined into a piping system by welding. It includes requirements for welding bevels, for external and internal shaping of heavy-wall components, and for preparation of internal ends (including dimensions and dimensional tolerances).

Our in-hourse R&D team developed bevel ends equipment are good using in thickness 2mm to 20mm pipe fittings, guarantee high efficiency and high quality.

Send us your technical drawings

These weld edge preparation requirements are also incorporated into the ASME standards (e.g., B16.9, B16.5, B16.34).

ASME B16.25 (BUTT WELD ENDS)

Buttweld Fittings general

A pipe fitting is defined as a part used in a piping system, for changing direction, branching or for change of pipe diameter, and which is mechanically joined to the system.

There are many different types of fittings and they are the same in all sizes and schedules as the pipe.

End cap size data

Pipe Cap are used for connecting pipes of different diameters and find wide applications in various chemicals, construction industries, paper, cement & ship builders

| Out diameter | High size | Wall thickness accord to 'E' | ||

| DN | NPS | E | E1 | E |

| 15 | 1/2 | 25 | 25 | 3.73 |

| 20 | 3/4 | 25 | 25 | 3.91 |

| 25 | 1 | 38 | 38 | 4.55 |

| 32 | 11/4 | 38 | 38 | 4.85 |

| 40 | 11/2 | 38 | 38 | 5.08 |

| 50 | 2 | 38 | 44 | 5.54 |

| 65 | 21/2 | 38 | 51 | 7.01 |

| 80 | 3 | 51 | 64 | 7.62 |

| 90 | 31/2 | 64 | 76 | 8.08 |

| 100 | 4 | 64 | 76 | 8.56 |

| 125 | 5 | 76 | 89 | 9.53 |

| 150 | 6 | 89 | 102 | 10.97 |

| 200 | 8 | 102 | 127 | 12.7 |

| 250 | 10 | 127 | 152 | 12.7 |

| 300 | 12 | 152 | 178 | 12.7 |

| 350 | 14 | 165 | 191 | 12.7 |

| 400 | 16 | 178 | 203 | 12.7 |

| 450 | 18 | 203 | 229 | 12.7 |

| 500 | 20 | 229 | 254 | 12.7 |

| 550 | 22 | 254 | 254 | 12.7 |

| 600 | 24 | 267 | 305 | 12.7 |

| 650 | 26 | 267 | ||

| 700 | 28 | 267 | ||

| 750 | 30 | 267 | ||

| 800 | 32 | 267 | ||

| 850 | 34 | 267 | ||

| 900 | 36 | 267 | ||

| 950 | 38 | 305 | ||

| 1000 | 40 | 305 | ||

| 1050 | 42 | 305 | ||

| 1100 | 44 | 343 | ||

| 1150 | 46 | 343 | ||

| 1200 | 48 | 343 | ||

- Size range: 1/2 to 56 inches (DN15 to DN1400)

- Pressure: SCH5 to SCH160v

- Wall Thickness:sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, sch120, sch140, sch160, xxs, sch5s, sch20s, sch40s, sch80s

- Max. wall thickness: 200mm

Size range of A234 WPB Large Diameter Pipe Cap

| OD | ND | INCH | SCH20 | SCH40 | SCH80 | STD | XS |

| Weight | Weight | Weight | Weight | Weight | |||

| 88.9 | 80 | 3 | 0.66 | 0.92 | 0.66 | 0.92 | |

| 114.3 | 100 | 4 | 1.17 | 1.67 | 1.17 | 1.67 | |

| 141.3 | 125 | 5 | 1.91 | 2.78 | 1.91 | 2.78 | |

| 168.3 | 150 | 6 | 2.9 | 4.47 | 2.9 | 4.47 | |

| 219.1 | 200 | 8 | 4.09 | 5.19 | 8.05 | 5.19 | 8.05 |

| 273 | 250 | 10 | 6.36 | 9.15 | 12.5 | 9.15 | 12.5 |

| 323.8 | 300 | 12 | 9.08 | 14.4 | 26.8 | 13.2 | 17.3 |

| 355.6 | 350 | 14 | 13.2 | 18.8 | 34.5 | 15.9 | 20.4 |

| 406.4 | 400 | 16 | 16.8 | 26.7 | 47.7 | 20.4 | 26.3 |

| 457.2 | 450 | 18 | 24.8 | 41.8 | 67.7 | 25.9 | 33.6 |

| 508 | 500 | 20 | 32.2 | 54.9 | 91.3 | 32.2 | 42.7 |

| 558.8 | 550 | 22 | 37.7 | 49.9 | |||

| 609.6 | 600 | 24 | 46.3 | 93.1 | 155 | 46.3 | 59.5 |

Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

Depending on their construction, pipe caps contain threaded cap, tapered cap and anti-roll cap etc.

DIN 2617 Pipe End Cap Dimensions

| WDR | |||||

| 3 | 4 | 5 | |||

| DN | d1 | s | s | s | h |

| 15 | 21.3 | 2 | 3.2 | 4 | 25 |

| 20 | 26.9 | 2.3 | 3.2 | 4 | 25 |

| 25 | 33.7 | 2.6 | 3.2 | 4 | 38 |

| 32 | 42.4 | 2.6 | 3.6 | 4 | 38 |

| 40 | 48.3 | 2.6 | 4 | 5 | 38 |

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 38 |

| 65 | 76.1 | 2.9 | 5 | 7.1 | 38 |

| 80 | 88.9 | 3.2 | 5.6 | 8 | 51 |

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 64 |

| 125 | 139.7 | 4 | 6.3 | 10 | 76 |

| 150 | 168.3 | 4.5 | 7.1 | 11 | 89 |

| 200 | 219.1 | 6.3 | 8 | 12.5 | 102 |

| 250 | 273 | 6.3 | 8.8 | 14.2 | 127 |

| 300 | 323.9 | 7.1 | 10 | 16 | 152 |

DIN 28011 Pipe End Cap Dimensions

ISO - dimensions

| dimensions d1 x s | height L | weight / kg |

| 21,3 x 2,0 | 9,0 | 0,01 |

| 26,9 x 2,0 | 9,0 | 0,01 |

| 33,7 x 2,0 | 13,0 | 0,02 |

| 42,4 x 2,0 | 13,0 | 0,04 |

| 48,3 x 2,0 | 13,5 | 0,05 |

| 60,3 x 2,0 | 18,5 | 0,07 |

| 76,1 x 2,0 | 20,5 | 0,10 |

| 88,9 x 2,0 | 25,0 | 0,15 |

| 114,3 x 2,0 | 28,0 | 0,26 |

| 114,3 x 3,0 | 29,0 | 0,39 |

| 139,7 x 3,0 | 38,5 | 0,60 |

| 168,3 x 3,0 | 47,5 | 0,90 |

| 219,1 x 3,0 | 63,5 | 1,32 |

| 273,0 x 3,0 | 93,0 | 1,95 |

| 323,9 x 3,0 | 102,0 | 2,70 |

| 355,6 x 3,0 | 109,0 | 3,80 |

| 406,4 x 3,0 | 123,0 | 5,00 |

| 457,2 x 3,0 | 123,0 | 6,10 |

| 508,0 x 3,0 | 133,0 | 7,60 |

Metric dimensions

| dimensions d1 x s | height L | weight / kg |

| 20,0 x 2,0 | 9,0 | 0,02 |

| 25,0 x 2,0 | 9,0 | 0,03 |

| 30,0 x 2,0 | 13,5 | 0,03 |

| 35,0 x 2,0 | 13,5 | 0,04 |

| 44,0 x 2,0 | 15,0 | 0,04 |

| 54,0 x 2,0 | 15,0 | 0,05 |

| 70,0 x 2,0 | 19,5 | 0,07 |

| 84,0 x 2,0 | 24,0 | 0,15 |

| 104,0 x 2,0 | 28,0 | 0,20 |

| 129,0 x 2,0 | 37,0 | 0,36 |

| 154,0 x 2,0 | 43,0 | 0,50 |

| 156,0 x 3,0 | 44,0 | 0,94 |

| 204,0 x 2,0 | 62,0 | 0,80 |

| 206,0 x 3,0 | 63,0 | 1,20 |

| 254,0 x 2,0 | 72,0 | 1,30 |

| 256,0 x 3,0 | 73,0 | 1,95 |

| 306,0 x 3,0 | 83,0 | 2,50 |

Cap geometry

| Out diameter | High size | Wall thickness accord to 'E' | ||

| DN | NPS | E | E1 | E |

| 15 | 1/2 | 25 | 25 | 3.73 |

| 20 | 3/4 | 25 | 25 | 3.91 |

| 25 | 1 | 38 | 38 | 4.55 |

| 32 | 11/4 | 38 | 38 | 4.85 |

| 40 | 11/2 | 38 | 38 | 5.08 |

| 50 | 2 | 38 | 44 | 5.54 |

| 65 | 21/2 | 38 | 51 | 7.01 |

| 80 | 3 | 51 | 64 | 7.62 |

| 90 | 31/2 | 64 | 76 | 8.08 |

| 100 | 4 | 64 | 76 | 8.56 |

| 125 | 5 | 76 | 89 | 9.53 |

| 150 | 6 | 89 | 102 | 10.97 |

| 200 | 8 | 102 | 127 | 12.7 |

| 250 | 10 | 127 | 152 | 12.7 |

| 300 | 12 | 152 | 178 | 12.7 |

| 350 | 14 | 165 | 191 | 12.7 |

| 400 | 16 | 178 | 203 | 12.7 |

| 450 | 18 | 203 | 229 | 12.7 |

| 500 | 20 | 229 | 254 | 12.7 |

| 550 | 22 | 254 | 254 | 12.7 |

| 600 | 24 | 267 | 305 | 12.7 |

| 650 | 26 | 267 | ||

| 700 | 28 | 267 | ||

| 750 | 30 | 267 | ||

| 800 | 32 | 267 | ||

| 850 | 34 | 267 | ||

| 900 | 36 | 267 | ||

| 950 | 38 | 305 | ||

| 1000 | 40 | 305 | ||

| 1050 | 42 | 305 | ||

| 1100 | 44 | 343 | ||

| 1150 | 46 | 343 | ||

| 1200 | 48 | 343 | ||