Stainless stub end

Stainless stub end are fittings used in place of welded flanges where rotating back up flanges are desired.

Leading Manufacturer and Exporter of Stainless Steel Stub End such as Stainless Steel Stub Ends ASTM A403, Stainless Steel Stub End 304L, Stainless Steel Stub End 316L, Stainless Steel Stub End 317, Stainless Steel Stub End 317L, Stainless Steel Stub Ends and many more items from China.

- Minimum lap thickness shall not be less than nominal wall thickness.

- Contact faces of stub ends shall have a concentric serration or spiral according to the purchaser's requirements.

- These lengths and radius apply for schedule 40s or thinner stainless steel pipes.

- Radius of fillet B is only effective to MSS SP-43 lap joint stub ends.

Lap Joints are consisted of three series.

| Nominal Pipe Size |

Outside Diameter at Bevel |

Length | Radius of Fillet | Diameter of Lap | |

| A | B | ||||

| NPS | D | L | R | G | |

| 1/2 3/4 1 |

21.3 26.7 33.4 |

51 51 51 |

3.0 3.0 3.0 |

0.8 0.8 0.8 |

35 43 51 |

| 11/4 11/2 2 |

42.2 48.3 60.3 |

51 51 64 |

5.0 6.0 8.0 |

0.8 0.8 0.8 |

64 73 92 |

| 21/2 3 31/2 |

73.0 88.9 101.6 |

64 64 76 |

8.0 10.0 10.0 |

0.8 0.8 0.8 |

106 127 140 |

| 4 5 6 |

114.3 141.3 168.3 |

76 76 89 |

11.0 11.0 13.0 |

0.8 1.6 1.6 |

157 185 218 |

8 |

219.1 273.0 323.8 |

102 127 152 |

13.0 13.0 13.0 |

1.6 1.6 1.6 |

270 324 381 |

| 14 16 18 |

355.6 406.4 457.0 |

152 152 152 |

13.0 13.0 13.0 |

1.6 1.6 1.6 |

413 470 533 |

| 20 22 24 |

508.0 559.0 610.0 |

152 152 152 |

13.0 13.0 13.0 |

1.6 -- 1.6 |

584 641 692 |

- Type A & B Stub Ends are made similar to forging pipe fittings such as elbows and tees.

- Type C Stub Ends are made by customized dimensions.

Benefits of lap joint stub ends

The use of lap joint stub ends has these two advantages:

Reduces the overall cost of the flanged joint

Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Example:

For an SS316 pipe, instead of using a full 316 welding neck flange, a combination of an SS316 stub end and a carbon steel lap joint flange would do the same exact job, but the total weight of SS316 material would be lower, and the cost as well.

Essentially, stub ends allow to minimize the weight of high-grade material in stainless, duplex, and nickel alloy piping, saving costs. Of course, the bigger the diameter and the class of the flanges, the higher the saving!

Facilitates the installation of the flange

The lap joint flange can be rotated on the pipe and simplify the alignment of the bolt holes of the mating flanges

It shall be noted that stud ends are becoming popular also in high-pressure applications (whereas they were used for low-pressure applications only in the past).

Stub ends dimensions

The chart shows the MSS and ANSI stub end dimensions in inches.

| Nominal Pipe Size |

Outside Diameter at Bevel |

Length | Radius of Fillet | Diameter of Lap | |

|---|---|---|---|---|---|

| A | B | ||||

| NPS | D | L | R | G | |

| 1/2 3/4 1 |

21.3 26.7 33.4 |

51 51 51 |

3.0 3.0 3.0 |

0.8 0.8 0.8 |

35 43 51 |

| 11/4 11/2 2 |

42.2 48.3 60.3 |

51 51 64 |

5.0 6.0 8.0 |

0.8 0.8 0.8 |

64 73 92 |

| 21/2 3 31/2 |

73.0 88.9 101.6 |

64 64 76 |

8.0 10.0 10.0 |

0.8 0.8 0.8 |

106 127 140 |

| 4 5 6 |

114.3 141.3 168.3 |

76 76 89 |

11.0 11.0 13.0 |

0.8 1.6 1.6 |

157 185 218 |

8 |

219.1 273.0 323.8 |

102 127 152 |

13.0 13.0 13.0 |

1.6 1.6 1.6 |

270 324 381 |

| 14 16 18 |

355.6 406.4 457.0 |

152 152 152 |

13.0 13.0 13.0 |

1.6 1.6 1.6 |

413 470 533 |

| 20 22 24 |

508.0 559.0 610.0 |

152 152 152 |

13.0 13.0 13.0 |

1.6 -- 1.6 |

584 641 692 |

The Stub End is available with us in different specifications, which find applications in a piping system to allow quick disconnection of the particular section involved.

Stub End is the fitting that be used in place of welded flanges where rotating back up flanges are desired.

MSS Type A stub ends are the industry norm and are utilized with standard flat face lap joint flanges. The lap thickness of the stub end typically meets the thickness of the schedule pipe it accompanies, and the exterior of the base has a curved machine radius for the lap joint flange to mate flush over the stub end. There are many instances in which lead time is critical and of more importance than adherence to existing ANSI / ASME flange specifications, and as such our customers will often choose to purchase a slip on flange and have the face machined to meet the radius requirement of the corresponding stub end piece.

ROC R16.9 2 1/2" SCH 40S A403 WPS304L

DIMENSIONAL TOLERANCES OF STUB ENDS MSS SP-43

The MSS standard is the regular length stub end and the most commonly used in the flange industry.

Stubend geometry

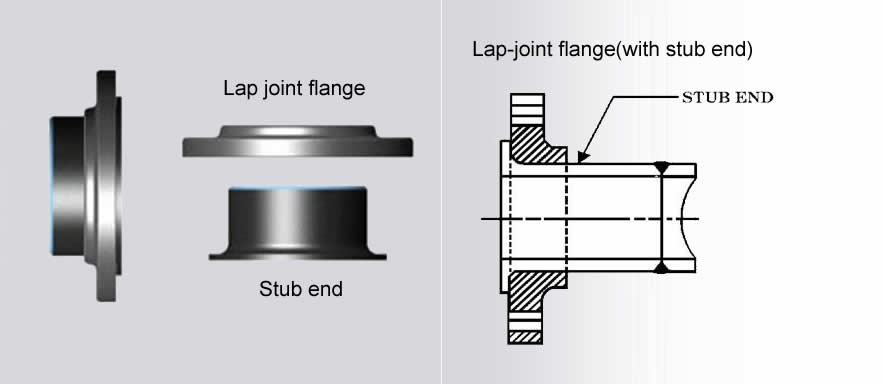

The Stub End, which essentially a short length of pipe, which has one end that is flared outwards and the other end prepared to be welded to pipe of the same Nominal Pipe Size (NPS), material and of a similar wall thickness. The Lap Joint Flange, which is a ring backing Flange and it is very similar in geometry to the Slip-on Flange.

Stub ends are mechanical joints that comprises of two components.

This type of flanged connection was also referred to as “Van Stone” or “Vanstone flare laps”, however this is an historic terminology and very rarely used technically or commercially.

| N.D. | Out diamater | Hight(F) | 翻边直径G | 倒角半径R | ||||

|---|---|---|---|---|---|---|---|---|

| NPS | DN | OD | Mss | ANSI | Nominal&max | Nominal&min | A Max | B Max |

| 1/2 | 15 | 21.3 | 50.8 | 76.2 | 35 | 34 | 3 | 0.8 |

| 3/4 | 20 | 26.7 | 50.8 | 76.2 | 43 | 42 | 3 | 0.8 |

| 1 | 25 | 33.4 | 50.8 | 101.6 | 51 | 50 | 3 | 0.8 |

| 11/4 | 32 | 42.4 | 50.8 | 101.6 | 64 | 63 | 4.8 | 0.8 |

| 11/2 | 40 | 48.3 | 50.8 | 101.6 | 73 | 72 | 6.4 | 0.8 |

| 2 | 50 | 60.3 | 63.5 | 152.4 | 92 | 91 | 7.9 | 0.8 |

| 21/2 | 65 | 73 | 63.5 | 152.4 | 105 | 104 | 7.9 | 0.8 |

| 3 | 80 | 88.9 | 63.5 | 152.4 | 127 | 126 | 9.6 | 0.8 |

| 31/2 | 90 | 101.6 | 76.2 | 152.4 | 140 | 139 | 9.6 | 0.8 |

| 4 | 100 | 114.3 | 76.2 | 152.4 | 157 | 156 | 11.2 | 0.8 |

| 5 | 125 | 141.3 | 76.2 | 203.2 | 186 | 185 | 11.2 | 1.6 |

| 6 | 150 | 168.3 | 88.9 | 203.2 | 216 | 215 | 12.7 | 1.6 |

| 8 | 200 | 219.1 | 101.6 | 203.2 | 270 | 269 | 12.7 | 1.6 |

| 10 | 250 | 273.1 | 127 | 254 | 324 | 322 | 12.7 | 1.6 |

| 12 | 300 | 323.9 | 152.4 | 254 | 381 | 379 | 12.7 | 1.6 |

| 14 | 350 | 355.6 | 152.4 | 304.8 | 413 | 411 | 12.7 | 1.6 |

| 16 | 400 | 406.4 | 152.4 | 304.8 | 470 | 468 | 12.7 | 1.6 |

| 18 | 450 | 457.2 | 152.4 | 304.8 | 533 | 531 | 12.7 | 1.6 |

| 20 | 500 | 508 | 152.4 | 304.8 | 584 | 582 | 12.7 | 1.6 |

| 22 | 550 | 559 | 152.4 | 304.8 | 641 | 639 | 12.7 | 1.6 |

| 24 | 600 | 610 | 152.4 | 304.8 | 692 | 690 | 12.7 | 1.6 |

STUB ENDS TYPICAL APPLICATIONS

The combination of stub ends and backing flanges is an alternative way to join pipes compared to the use of standard flanges.

This solution is used in these typical scenarios:

- Applications where rotating back flanges are preferred (to facilitate bolting)

- Pipelines in costly materials, as stainless steel, duplex, super-austenitic (example 6Mo), nickel alloy, titanium and zirconium: indeed, the use of stub ends for this type of pipelines helps End-Users and EPC Contractors reduce the total weight of the flanged joints and their total cost (example: in a stainless steel pipeline, carbon steel backing flanges can be used instead of standard stainless steel flanges – as they do not get in contact with the fluid conveyed by the pipeline – “unwetted materials”)

- High pressure pipelines

TYPES OF STUB ENDS

Stub ends are manufactured in three different types and two standard length.

Type “A”: this type is produced and machined to fit lap joint flanges.The mating surfaces of the stub end and the lap joint flange have a matching profile and surface. The lap thickness of type A stub ends is > = the minimum wall thickness of the connected pipe. The outside the stub end and the lap joint flange have a matching profile and surface. The lap thickness of type A stub ends is > = the minimum wall thickness of the connected pipe. The outside corner of type A has a radius to accommodate the lap join flange, whereas the inside corner is squared.

Type “B”: this type of stub ends is suited for standard slip-on flanges acting as lap-joint flanges. The lap thickness of type B stub ends is >= the minimum WT of the connecting pipe. The lap of these type of stub ends has generally a serrated face. To ensure tight joints, chamfers on the ID side of the flange are required.

Type “C”: this last type can be used both with lap joint and slip-on backing flanges and are fabricated out of pipes. The lap of C-type stub ends is flared over and the lap thickness is 75% of the connecting pipe WT. Type C has a short fillet outer radius able to host any back up flange.

Type “CS”: this type is similar to “C” with the difference that the lap face has concentric serrations machined during the manufacturing process.

Short / long pattern stub ends (ASA/MSS)

Short pattern (MSS) and long pattern stub ends (ASA)

Stub ends are available in two different patterns:

- the short pattern, called MSS-A stub ends

- the long pattern, called ASA-A stub ends (or ANSI length stub end)

Stub ends dimensions and weight

Dimensions and manufacturing tolerances are covered in ASME B16.9 - Butt Weld Fittings and MSS-SP-43 (JIS B2312, JIS B2313 may also apply).

Stub End come in three standard lengths, MSS SP43 or ANSI B16.9 short and long pattern. Short pattern stub ends are mostly used for flanges from class 300 to class 600 and above. Besides these standard types, End-Users and contractors can require stub ends with non-standard lengths to suit specific project’s requirement. This will of course come at an additional cost.

Ends/Face lap finishing

ASME B16.25 END WELDING BEVEL as right

The following types of ends may be ordered:

- Beveled Ends (generally ASME B16.25)

- Squared Ends

- Flanged Ends

- Victaulic Grooves

- Threaded Ends (Male Only)

Material for Stub Ends

Stub Ends are available in numerous ASTM and other international recognized materials, to match pipe specifications, as low alloy, stainless steel, austenitic-ferritic, high alloy steels (nickel alloy such as Inconel, Incoloy 800, Monel, Hastelloy C276), non-ferrous materials (copper, cupronickel 90 /10 and cupronickel 70 / 30) and titanium / zirconium / tantalum.

| Material | Grade | UNS Equivalent |

|---|---|---|

| A234 WPB Carbon Steel | B | K03006 |

| A403 Stainless Steel | 304/304L | S30403 |

| 304H | S30409 | |

| 316/316L | S31603 | |

| 316H | S31609 | |

| 317L | S31703 | |

| 904L | N08904 | |

| 309S/H | S30908 | |

| 310S | S31008 | |

| 321 | S32100 | |

| 6XN | N08367 | |

| 20CB | N08020 | |

| 347 | S34709 | |

| 254SMO | S31254 | |

| A815 Duplex /Super Duplex | 2205 | S31803/S32205 |

| Zeron 100 | S32760 | |

| 2507 | S32750 | |

| 410 | S41000 | |

| A366 Nickel Alloys | HC22 | N06022 |

| HB-3 | N10675 | |

| HG3 | N06985 | |

| HX | N06002 | |

| HC2000 | N06200 | |

| HC276 | N10276 | |

| NCI | N06600 | |

| NC | N04400 | |

| N | N02200 | |

| NL | N02201 | |

| NCMC | N06625 | |

| NICMC | N08825 | |

| NIC10 | N08810 | |

| NIC11 | N08811 |

Lap-joint flanges are most commonly available in carbon steel and low temperature carbon steel, because it is a lower cost than the Stub End that will be wetted by the service and it must be of a suitable grade of steel. If orientation and alignment of bolt holes is the only issue, then for standardization, then the Stub End and the Lap Joint Flange can be of the same material.

The most common material grade for stub end is the ASTM A403 / ASME SA403 (stainless steel stub ends). With reference to EU materials, the most common grades are DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404.

Stub Ends assembly

Stub ends and lap joint flanges can be assembled following this process:

- The Lap Flange is slipped over and onto the Stub end Flange.

- The Stub End Flange is then welded onto a pipe spool, using an approved Welding. Procedure Specification (WPS), by a qualified Welder. The Lap Joint Flange, backing Flange, can revolve around the Stub End, which is now attached to the piping spool.

- The bolt holes of the Lap Joint Flange can now be orientated and aligned with the bolt holes of a mating Flange of the same ASME designate rating and NPS.

- The Lap Joint Flange can be mated to any Flange covered in ASME B16.5, Weld Neck, Slip On, Threaded, Socket Weld, another Lap Joint Flange.

It can also be mated to a fabricated plate Flange with compatible, bolting dimensions.

Why use Stub Ends?

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

The two devices to be combined, in this case, are:

- The stub end, which is essentially a piece of pipe, with one end flared outwards and the other prepared to be welded to a pipe of the same bore size (NPS = nominal pipe size), material and wall thickness. The most widely used fabrication tool for stub ends is the flaring machine, which is able to flare the end of the pipe and then cuts it to length.

- A Lap Joint Flange, which is used to actually bolt the two lengths of pipe together.

Commercial benefits

Commercial advantages are that the Stub End, will be wetted and it must be made of a grade of material that meets the process design and service conditions of the pipeline. However, the Lap Flange is un-wetted and it can be made of a lower grade of material as long as it meets

the mechanical strength requirements of the piping systems.

This means that instead of:

Duplex Stub End and a Duplex Lap Joint, you could have Duplex Stub End and Carbon Steel Lap Flange.

Or you could have Stainless Stub End and Carbon Steel Lap Flange. There are other bimetallic combinations that result in a flange assembly that is commercially cheaper.

During recent years the price differential between Duplex/Stainless Steel and Carbon Steel has narrowed and this practice on large Projects has become less common, however a cost difference always exists (the higher the NPS and the length of the pipeline / piping system, the higher the saving). On the other hand, the warehousing cost of one single component, i.e. a Weld Neck Flange, requires less shelf space than the cost of warehousing a Lap Joint and a Stub End. End Users and Contractors shall determine the actual convenience of using stub ends, considering all these factors and generally the commercial advantage is still valid and it may suit certain situation, especially in “brownfield” modifications.

Installation benefits

The “loose” Flange concept of a Lap Joint, is very beneficial during field installation of piping systems. If two spools are to be mated up in the field, having one Flange that can be rotated is very advantageous when aligning the bolt holes, prior to the introduction of the Stub bolt and the accompanying nuts. The facility of easier orientation and alignment of bolt holes, is of particular use it there is a spool that

has to be removed frequently, if positive isolation is a process requirement.

Stub Ends limitations

A Lap Joint consists of two independent components that are not integrated with a weld and like for like in size/pressure class/material it lacks the mechanical strength and capabilities to withstand fatigue, like a one piece Weld Neck Flange or a welded together Slip On or Socket Weld Flanges. In cyclic services, collars EN 1092-1 type 35 PN 16-25-40 are used instead of stub ends (especially to close pumps and compressors). If carefully consideration is given to Process Design condition, the service and the final application, then a Lap Joint Flange mechanical connection are a valid and cheaper method for installing piping systems compared to the use of standard flanges.

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

The two devices to be combined, in this case, are:

- The stub end, which is essentially a piece of pipe, with one end flared outwards and the other prepared to be welded to a pipe of the same bore size (NPS = nominal pipe size), material and wall thickness. The most widely used fabrication tool for stub ends is the flaring machine, which is able to flare the end of the pipe and then cuts it to length.

- A Lap Joint Flange, which is used to actually bolt the two lengths of pipe together.

How to order a Stub Ends

The following information shall be provided to order a stub end:

- NPS

- Schedule

- Length (according to norms MSS SP43 / ASME B16.9 / custom)

- Specs and material grade

- Ends finish

- Execution: seamless / welded (wx)

Stub end finish

Stub ends can be ordered with different ends finishing:

- Beveled Ends

- Squared Ends

- Flanged Ends

- Grooved Ends

- Threaded Ends (Male Only)